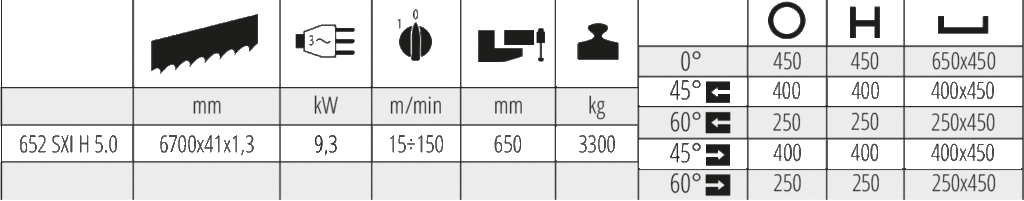

SHARK 652 SXI H 5.0, dual column electro-hydraulic band saw, equipped with blade 6700x41x1,3mm specifically designed to cut pipes and beams up to max 650x450mm at 0° and can miter from +60° up to -60°.

The machine is available in two versions both equipped with a simple touchscreen and the latest MEP controller which is designed exclusively for all our sawing machines.

– MANUAL POSITIONING (manual rotation of the head with a hand lever and a hydraulic brake to lock the head into position; the cutting angle is visualized on a display).

– AUTOMATIC POSITIONING (programming of the cutting angle from the electrical panel with automatic hydraulic locking system).

In the AUTOMATIC POSITIONING feature the cutting angle is determined by means of a gear/chain system and 2 cutting cycles are available.

A) AUTOMATIC CYCLE for cuts only at one angle

B) AUTOMATIC CYCLE for cuts with 2 angles programmed to be initiated alternatively.

To make the angle setting easier both versions A and B can be equipped with a pair of pop-up hydraulic rollers (one for the infeed and one for the outfeed). This avoids the material scraping onto the turn table when mitiring (OPTIONAL).

A FEW FEATURES: SHARK 652 SXI H 5.0

- Structure in sturdy cast iron, to absorb vibrations and give the machine a better cutting stability and longer blade life.

- Powerful 9,3kw (15hp) blade motor with vectorial inverter in order to continuously adjust the blade speed in a single range from 15 to 150m/min.

- Powerful coolant flows to wash the cutting area and to convey chips away.

- Work light and laser projector to position the bar accurately in order to carry out non-standard or facing cuts.

- Saw head stroke by means of double hydraulic cylinders on linear guides with ball-bearings and pre-loaded slides (3° canted head to make the chip removal easier for horizontal walls).

- Self-adjustment cutting force by means of a servo valve mounted on the hydraulic cylinder.

- Latest generation hydraulic control unit, with high efficiency and low energy consumption.

- 7 “ touch screen which visualizes.

- Two hydraulic cutting vises to clamp the material on both sides and one vertical hydraulic cylinder.

- Automatic adjustment of the front guide arm in relation to the capacity that needs to be cut.

- Adjustable blade-guide heads in steel, with roller and carbide pads.

- Servo control to shift idler pulley for blade changing (2200 kg).

- Three coolant pumps to ensure high coolant flood (120 l/min) to cool down the blade and wash away chips from the working area.

- Powered blade brush.

- Belt chip conveyor ( Optional).

- Machine can be handled with both lift truck and crane.

- BI-METAL band saw blade included.

ไทย

ไทย English

English