BAND SAW BLADES

Band saw blades are produced from diffrent materials such M42 to guarantee the highest performances while cutting all kind of materials normally used in mechanic workings. We can be supplied with different toothings according to customer needs.

Our quality standards continue to distinguish the precision bandsaw blades we produce for our partners all over the world. In order to actively maintain this high quality standard. our company has been certified according to the DIN EN ISO 9001:2015 quality management system since 1995.

MULTICUT

For cutting all usual types of steel up to a hardness of 45 HRc.

Our solution for:

• Single, layer and bundle cuts

• K-tooth: Sawing solid material

Advantages:

• Robust bandsaw blade with long service life

• Optimal for standard to high-alloyed materials

• Low noise level due to reduced vibrations

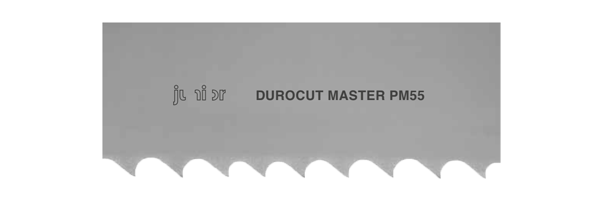

DUROCUT MASTER

Universal heavy duty blade designed for large cross sections also on lower alloyed steel grades.

Our solution for:

• Medium-size to large workpieces

• Thick-walled pipes

• Materials with tensile strength over 1400 N/mm2

• For materials WITHOUT residual stress

Advantages:

• Extended service life

• Lower cutting costs

• Heat resistance and wear resistance

• Fine to very fine cutting surface

• Reduced cutting channel compared to CrNiCut

PROBEAM

Tubes, beams and structurals

Our solution for:

• Profiles and beams

• Single, layer and bundle cuts for pipes and beams in

general steel construction and manufacturing industry

Advantages:

• No binding in the cutting channel

• Minimal tooth chipping, extremely long service life

• Vibration resistance

• Optimal surface quality

-

Alucut(Bimetal Sawblade M42)

อ่านเพิ่ม -

CrNiCut(Bimetal Sawblade M51)

อ่านเพิ่ม -

DUROCUT MASTER ( Bimetal Bandsaw Blades PM55 PREMIUM )

อ่านเพิ่ม -

Durocut(Bimetal Sawblade M51)

อ่านเพิ่ม -

Multicut(Bimetal Sawblade M42)

อ่านเพิ่ม -

Nirocut(Bimetal Sawblade M42)

อ่านเพิ่ม -

Powercut I Black(TCT Bandsaw Blade)

อ่านเพิ่ม -

Powercut I(TCT Bandsaw Blade)

อ่านเพิ่ม -

Powercut II A/B(TCT Bandsaw Blade)

อ่านเพิ่ม -

Powercut III(TCT Bandsaw Blade)

อ่านเพิ่ม -

Probeam(Bimetal Sawblade M42)

อ่านเพิ่ม -

Procut(Bimetal Sawblade M42)

อ่านเพิ่ม

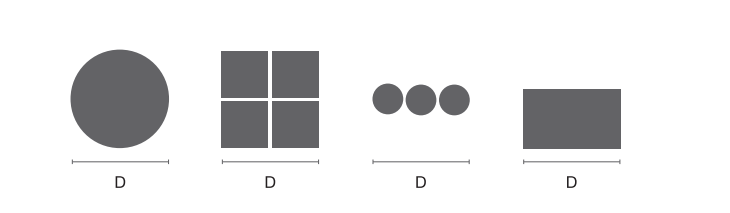

Tooth Types

Band saw blades To obtain optimum cutting ra- tes, tooth pitch and tooth design are of great importance, We offer various tooth pitches to solve your cutting problems.

Type M

This tooth type has ground tooth tips with a chamfered, non-set precutter and two set nishing cutters and is

generally manufactured with a positive rake angle. Its particular tooth

geometry allows economic cutting

of high and highest alloyed steels with bimetal bandsaw blades.

Type N

With a rake angle of 0°, this tooth type is particularly suited for cutting short chipping, low alloyed materials, solids in small and medium cross sections as well as tubes and pro les.

Type K/K+

With a positive rake angle of 10° or 16° (K+), the hook tooth has a large, long-drawn-out chip space. Therefore, it is mostly used for cutting non-ferrous metals, steels with a low content of carbon, Cr-Ni alloys, and primarily bigger cross sections.

Type P

The pro le tooth has a special geometry for a vibration-low cutting of beams, structurals and tubes.

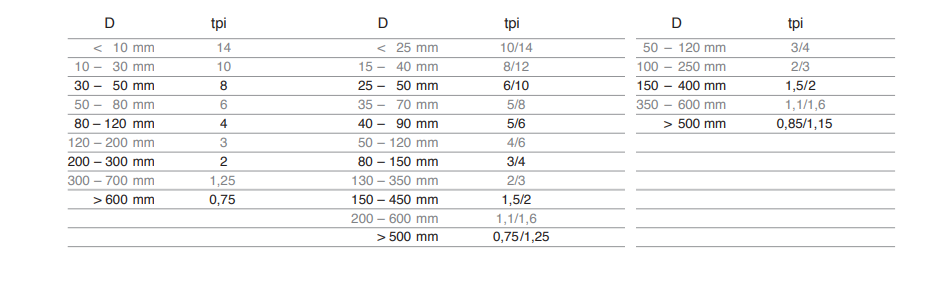

Tooth pitch recommendation Solid Material

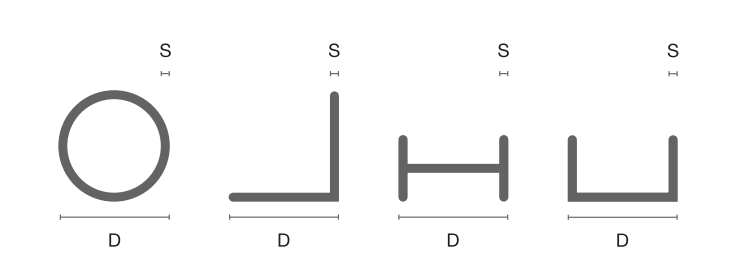

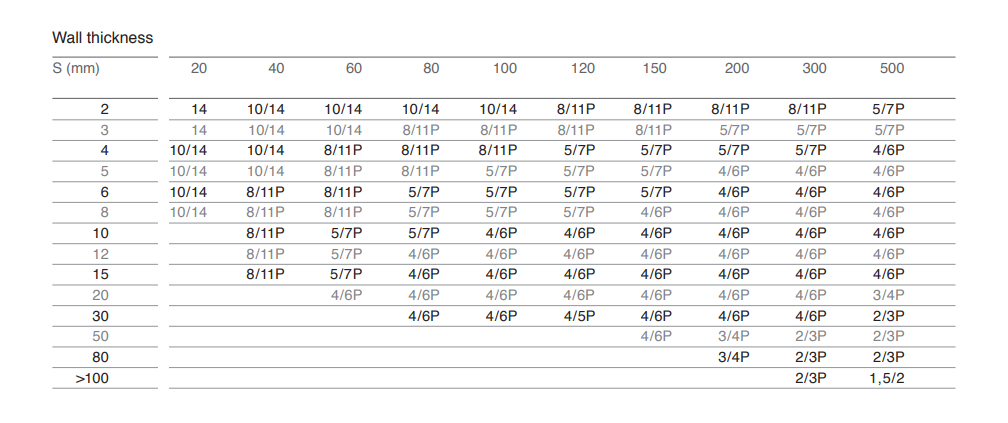

Tooth pitch recommendation Tubes and Profiles

POSSIBLE FAILURE CAUSES

PROBLEM

a) No clearance between body

back and flange of the wheels.

b) Worn back guides

SOLUTION

a) Adjust wheels.

b) Replace back guides.

PROBLEM

Body cracks caused by worn

back guides. Leading to the

back edge of the blade

becoming brittle.

SOLUTION

Replace back guides.

PROBLEM

Worn or incorrectly adjusted

brushes are reducing the life of

the saw blade.

SOLUTION

Adjust brushes regularly and

replace when worn.

PROBLEM

Incorrect alignment causes

burrs at the band back edge,

followed by microcracks.

Result: Blade breakage.

SOLUTION

Adjust wheels. Keep a

clearance between band back

edge and flange of the wheels.

(Recommended clearance:

0.5 to 1.5mm).

PROBLEM

The constant rubbing along the

band saw back edge has

induced a brittleness.

Microcracks appear.

RESULT: Blade breakage

SOLUTION

Replace back guides.

PROBLEM

Too tight or blocked

damping rollers may lead to

rupture of the body.

SOLUTION

Reduce the contact

pressure so the rollers can

be rotated with little effort in

passive state. Replace

blocked damping rollers.

PROBLEM

Too strongly adjusted or

damaged side guides cause

formation of microcracks and

blade breakage.

SOLUTION

Reduce pressure.

Clean side guides.

PROBLEM

The tooth gullet is too small.

To much frictional heat is generated.

Result: Heavy wear and cut deviation.

SOLUTION

Select a coarser tooth pitch

PROBLEM

The tooth gullet is too small.

Chips will overfill the tooth gullet

and lift the blade. When the chip

clears the gullet, the blade will

be forced back into the cutting

channel resulting in a shock load

on the tooth. Leading to tooth

damage.

SOLUTION

Select a coarser tooth pitch

PROBLEM

Teeth have no guide in the

cutting channel. Resulting in

high tooth loads at the cutting

point. Result: Fractures and

breakages as well as

microcracks in the tooth gullet.

SOLUTION

Use finer tooth pitch.

ไทย

ไทย