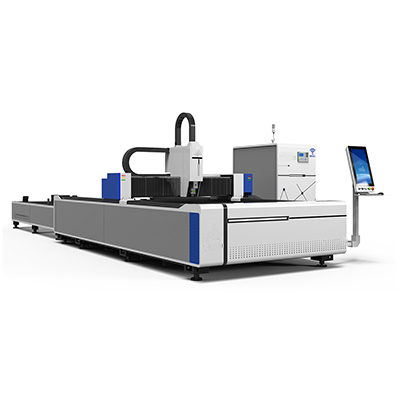

TCTET-ET

The fiber laser cutting machine adopts 12-16mm plate welding lath bed, chain exchange platform and professional CNC cutting system to provide users with powerful cutting ability and efficiency. At the same time, the top imported parts and strict assembly process ensure the machine safe, efficient and high-precision stable operation.

Model | TCTET-ET3015 |

Working Area | 3000*1500mm |

Laser Output Power | 1000-6000W |

Max Speed | 140m/min |

Product advantage Heavy Duty Plate Welding Bed Machine bed is welded with 12-16mm thick carbon structural steel dislocation honeycomb structure, machined after stress relief and annealing, then vibration-aging and natural aging treatment, so that the welding and machining stress can be completely eliminated, to ensure excellent rigidity and high precision of the bed, reducing the machining error caused by the vibration of the bed.Super touch screen industrial computer The screen adopts high definition capacitive touch screen, equivalent to positioning accuracy of ipad. The powerful waterproof and breathable system makes the space breathe and use more smoothly. High definition plasma tempered glass makes the screen more delicate and comfortable to operate. Supper large display menu layout is simple and intuitive, built-in cutting parameters to improve machining reliability.

Super fast exchange platform Cylinder lock, chain-type transmission, let the machine running more stable. Table roller adopts eccentric wheel structure to ensure the height of each wheel is consistent and play the supporting role. Platform exchange time super fast, finish in 10S, high efficiency.

Partition dust removal system Independent R&D of forced cooling way, remove the dust for each processing area separately. Simple structure, good effect in sealing exhausting, low energy consumption, improve the dust removal effect in this area, workpiece much better, and also solved the environment pollution, and bring effective protection for operators and machine.

ไทย

ไทย English

English