Shark 660 CNC HS 4.0, automatic double-column bandsaw for 0° cuts on structural, stainless, alloy steels, profiles ,solid parts and profiles with dimensions up to 660x660mm.

– CNC machine with a new controller: MEP 40.

It has been specifically designed by MEP for the automation of its range of products.

– This sawing machine also features a semiautomatic cutting cycle and uses latest generation technologies;

indeed, Shark 660 CNC HS 4.0 is equipped with a NEW controller with processor RISC 32 bit 200 MHz

with integrated interface to:

– Install a GSM card (OPTIONAL) to send an SMS to the programmed number notifying the type of emergency occurred while the machine was operating unattended.

– Connect to an Ethernet network for the remote assistance service.

– Get software updates and changes by e-mail, that are transferred to USB port by SD or MMC card and later on the control memory, through the suitable slot on the control console.

– Choose in the library (that can be extended by the user) the material type, geometry and hardness, the type of band to be used and the control automatically sets: position of the cutting head , feed rate and the blade rotation speed.

OTHER FEATURES:

- 8” touch screen display operator interface and push buttons for all functions of the sawing machine. It is simple and intuitive, with a self-learning feature it guarantees a reliable use and it controls all cutting parameters in real time.

- Automatic acquisition of the actual starting point of the cut.

- CNC machine to store up to 300 cutting programs each with different quantity and length.

- Structure in sturdy cast iron, to absorb vibrations and give the machine a better cutting stability and longer blade life.

- Cutting head downfeed movement with 2 brushless motors and with recirculating ballscrews-nut, with hydraulic compensation of the cutting head.

- The cutting head movement is with linear guides and ball-recirculating pre-charged slides.

- Hydraulic power pack to supply the feeding vices, cutting vices and carbide pads.

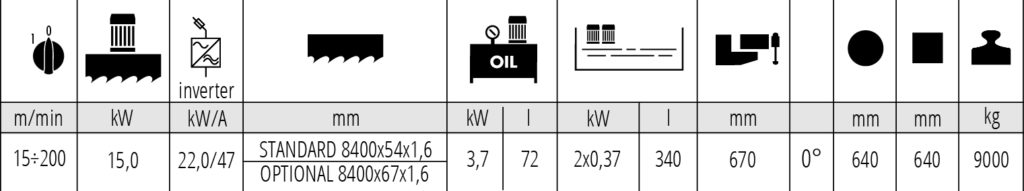

- Infinitely adjustable cutting speed from 15 to 200 m/min by vector inverter.

- Bar feeder with recirculating balls, screw/nut and stepper motor (feeding length in one stroke 760 mm or 30” that can be repeated in order to cut any length)

- Self-aligning feeder vice unit for feeding even strained bars.

- Rest piece that can no longer be in-feeded automatically by feeder: 70mm.

- Driving and idler pulley locked by conical clamping ring.

- Software to control/assess/correct in real time: – cutting force – cutting torque and band tensioning against the programmed values.

- Control panel, with and adjustable frame, assembled on a rotating arm.

- Adjustable blade guide blocks. This system, that guides the blade, is a combination of pre-charged rollers and carbide inserts.

- Idler pulley movement from the keyboard to replace the band easily.

- Automatic adjustment of the front blade-guide head according to the dimensions of the bars to be cut.

- Blade deviation device.

- Laser projector to position the bar accurately to carry out non-standard or facing cuts.

- Band rotation control with stop in real time in case of blade jammed.

- Electro-mechanical servo-system for the blade dynamic tensioning.

- Coolant tank incorporated in the base.

- Blade cooling with lubricating oil by means of two coolant pumps. Each pump has a 120l/min flow rate.

- Wash gun to clean the machine.

- Powered blade brush.

- Chip conveyor.

- Sound and flashing indicator.

- Bimetallic band for profiles and solid pieces.

- Service keys and instructions manual, for maintenance and spare parts list.

ไทย

ไทย English

English